Oil free air compressor for laser cutting

2020年,The laser cutting industry has ushered in earth-shaking changes,In the laser cutting industry,More customers choose laser cutting special compressors to replace traditional air compressors,This makes the customer's processing and manufacturing costs greatly reduced,同时,Faster!Laser cutting is divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture。Laser melting cutting is the use of laser heating to melt metal materials, and then through the nozzle coaxial with the beam of non-oxidizing gas (N2, Ar, He, etc.), relying on the strong pressure of the gas to eliminate liquid metal, forming a slit。Laser melting cutting is mainly used for the cutting of some non-oxidizing materials or active metals, such as stainless steel, titanium, aluminum and its alloys, etc., with high cutting quality。With the transformation and upgrading of the industrial manufacturing industry, the laser industry has ushered in the spring, and the cutting technology has been vigorously expanded in many fields, which is of great significance to promote the development of the industry。Laser cutting technology has the characteristics of intelligence, high efficiency and high quality, and has a very broad application in various machinery manufacturing and processing industries such as rail transit, automobile, construction machinery, electrical manufacturing, household appliances, etc。As we all know, when laser cutting processing, if you want to improve its processing effect, we can appropriately add some auxiliary gases, such as air, oxygen and nitrogen。The air compressor is mainly used to compress air, and then provide high pressure air supply to the cutting head part and the cylinder of the workbench。The gas of the cutting head of the laser cutting machine is mainly used to blow away burrs and residue。The last part is used to clean the dust of the optical path system,The compressed air discharged from the air enters the air control cabinet through the gas storage tank and the dryer,And through a sophisticated processing system,Into a clean, dry gas,Finally, it divides into three ways,As cutting gas, cylinder power gas source and light path positive pressure dust removal gas to maintain the normal operation of the laser cutting machine。

Among them, air is the lowest cost auxiliary gas, which is also the choice of many customers。Therefore, auxiliary equipment air compressor is essential, then how to buy the air compressor of laser cutting machine?

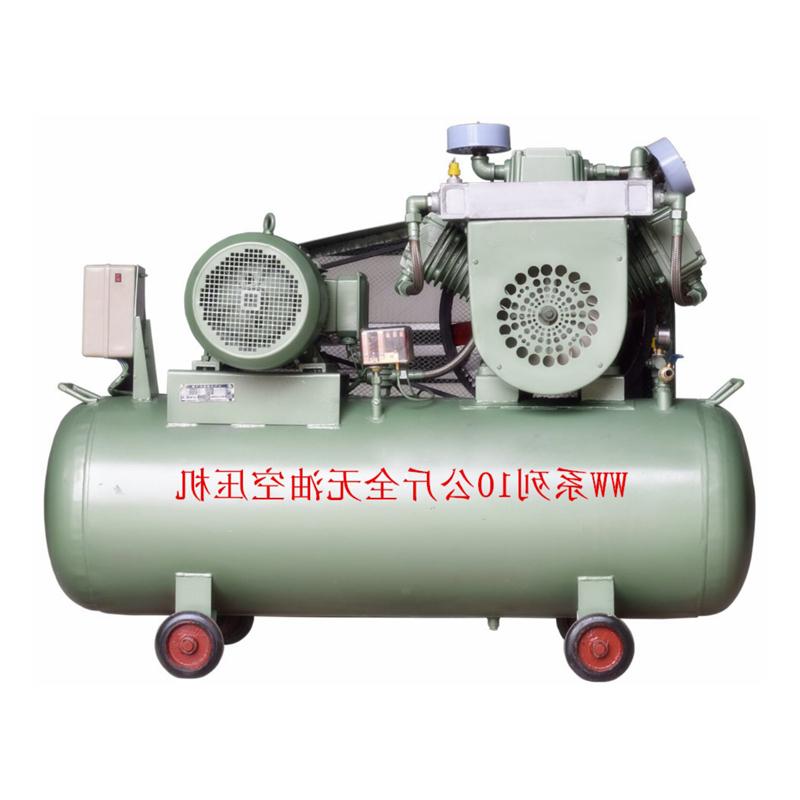

The air compressors commonly used in the laser cutting industry can be divided into oil air compressors and air compressorsOil-free air compressor两种:

1The air compressor with oil causes a great waste of lubricating oil, which is extremely unfavorable to the operation of the laser cutting machine, which can easily lead to oil and water or dirty substances in the protective lens of the laser cutting machine, which makes the optical path of the laser cutting machine deviate or sometimes cut through in the process of cutting。

2、 Laser cutting oil-free compressor, has the following characteristics: the whole machine is oil-free, without any pollution;Heavy duty cast iron design, stability, better reliability;Continuous gas supply, in the laser cutting industry, faster than nitrogen6%。

Oil-free air compressor because the compressed air is almost oil-free, this provides stable conditions for the operation of the laser cutting machine, and the laser cutting machine is unconventional, and the requirements for use are also very high。No water, no oil required。Because these things are very easy to cause damage to the laser cutting machine。

The maximum pressure of the oil-free air compressor developed by our factory can be reached18公斤,Fully adapted to the laser cutting industry,The whole machine adopts imported bearings,Piston ring guide rings are specially customized,Fully ensure the normal operation of the machine,The service life of the machine is greatly enhanced,To save energy and reduce noise,The enclosure was also soundproofed,And the use and maintenance costs are low,No regular maintenance is required,Cost savings for customers。